What is Functional Safety?

Determining SIL Requirement SIL Verification

Functional Safety (FS) means protecting the system against hazards arising from faulty and interrupted functionality. In the process industry, the hazard that exists due to the nature of the processes is primarily tried to be limited by design. In addition to the right design, we try to operate the production processes efficiently and safely by keeping the basic process control systems and alarms and variations within acceptable limits. In cases where the basic process control system is insufficient, safety instrumented systems designed within the scope of functional safety undertake the task of protecting our process from major accidents.

It is aimed to plan the right investment for scenarios with high risk levels determined by functional safety studies and process hazard analyzes and to operate processes by making installations in accordance with the planned.

Determining SIL Requirement

Process hazard analyzes carried out within the scope of Process Safety are carried out by identifying hazards, evaluating and analyzing risks and managing them. The identification of process hazards can be carried out using qualitative techniques such as the HAZOP Study. However, when it comes to the planning of investments, it is necessary to determine the numerical equivalents of the safety instrumented functions (SIF) created using hazard determination tools.

At this point, IEC 61508 and IEC 61511 standards allow us to determine the level of safety integrity within Functional Safety.

According to IEC 61508 and IEC 61511, the SIL requirement can be determined using the following methods.

- ALARP Method

- Risk Graph Method

- Risk Matrix Method

- Fault Tree Analysis (FTA)

- Layers of Protection Analysis (LOPA)

SIL Verification

Verification means the process of establishing the truth, accuracy, or validity of something. After determining the SIL level needed in Functional Safety Engineering studies, the studies carried out to determine whether the designed system architecture and the equipment and instruments to be used meet the required SIL level are called SIL Verification.

SIL Verification indicates the capability of a Safety Instrumented Function (SIF) in accordance with IEC 61508 and IEC 61511 against the following requirements.

- Measuring the impact of random hardware failures (Probability of Failure on Demand (PFD) or Average Frequency of Hazardous Failures (PFH))

- Hardware security integrity architectural constraints (Safe Failure Fraction (SFF), Hardware Fault Tolerance (HFT), Element Type A or B)

- Systematic capability

- Common cause failure (CCF)

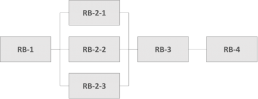

Fault Tree Analysis (FTA), Failure Modes and Effects Criticality Analysis (FMECA), and Reliability Block Diagrams (RBDs) are used when performing SIL Verification studies.

Where SIF fails to achieve the target failure measure or SIL, a sensitivity analysis can be performed to show the effect of changing certain factors. The following examples can be used for these factors;

- Maintenance strategy

- System architecture

- Establishment of fault diagnosis mechanisms

- Engineering studies to reduce the probability of common cause failure

The following information is needed to carry out SIL Verification studies.

- SIL requirement determination report of the system to be verified.

- Process hazard analysis report that is input to the SIL requirement determination report.

- Piping and instrumentation diagram (P&ID)

- Cause and Effect Matrix (C&EM)

- Interlock list and configuration

- Data sheets containing reliability data for equipment and instruments.

Important Definitions of Functional Safety

| Safety Instrumented Function | SIF | A combination of sensors, logic analyzers, and end elements that detect an abnormal condition, secure the process without human intervention, or initiate a safety-trained operator response and have a specified safety integrity level (SIL). |

| Security Integrity Level | SIL | The failure probability of the safety instrumented function (SIF) failing to fulfill the performance criterion of the safety instrumented function (SIF) and its function in case of demand |

| Safety Instrumented System | SIS | Combination of sensors, logic analyzers and end elements that perform one or more safety instrumented functions (SIF) |

| Probability of Failure on Demand | PFD | The probability that a system will not be able to perform a certain action on demand |

Our Services

Our Trainings

Keywords: Functional Safety, Security Integrity Level, SIL, SIL Verification, SIL Requirement, FTA, Fault Tree Analysis

Takipte Kalın

Takipte Kalın